Rockwell Automation's 8th annual State of Smart Manufacturing Report reveals a focus on delivering profitable growth without sacrificing quality, an emphasis on accessing data's true potential, and increasing the adoption of technology to build resilience, enable agility, increase sustainability, and address workforce challenges.

The key findings include:

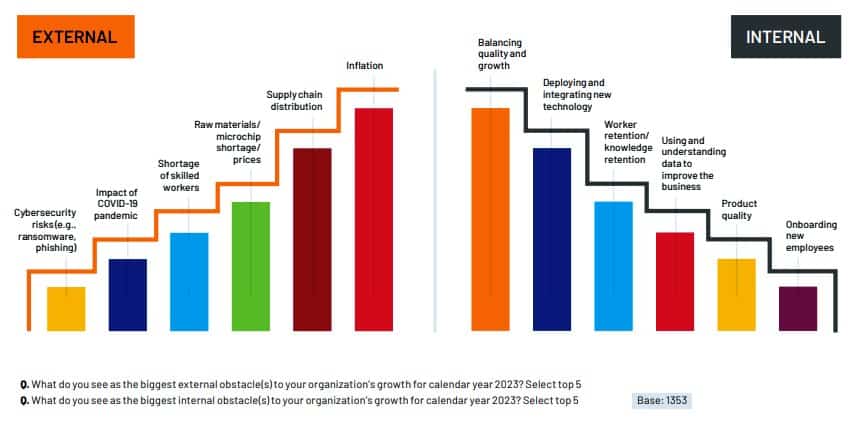

- "Balancing quality and growth," and "tracking or quantifying sustainable practices" are the biggest internal obstacles inhibiting progress for Asia-Pacific (APAC) manufacturers this year, compared to deploying and integrating new technology in 2022.

- Globally, twice as many manufacturers believe their organisation lacks the technology needed to outpace the competition, as compared to 2022.

- Four out of five manufacturers still lack an end-to-end supply chain planning solution.

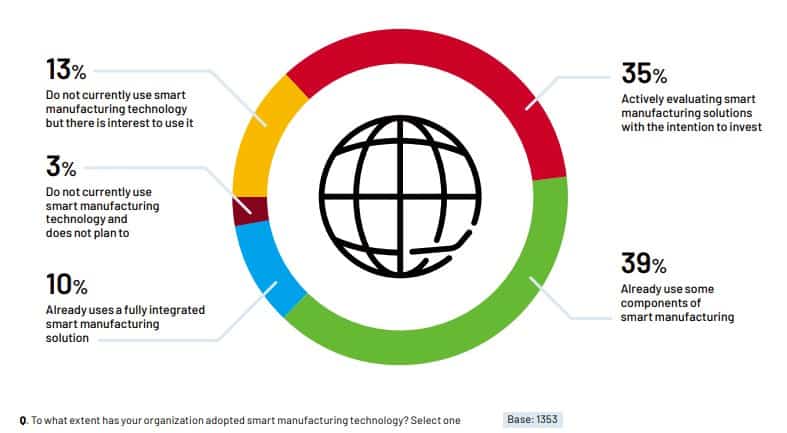

- 44% of APAC manufacturers plan to adopt smart manufacturing within the next year; out of this, China (80%), Australia (60%) and India (59%) are already using some components of smart manufacturing.

- The biggest barriers to adopting smart manufacturing for APAC manufacturers are employee resistance to technology adoption and change, lack of skill set to manage smart manufacturing implementation, and lack of clear definition of the value/ROI of smart manufacturing.

- Quality management system (QMS) is the smart manufacturing system that APAC respondents have seen the largest ROI, followed by manufacturing execution system (MES) and enterprise resource planning (ERP).

- Cybersecurity risks rank highest as the obstacle all respondents are looking to mitigate with smart manufacturing initiatives.

- 88% of APAC manufacturers plan to maintain or grow employment due to technology adoption. Additionally, 39% of respondents believe they will be able to repurpose existing workers due to their increasing use of technology.

- Of the 94% of APAC manufacturers who have formal or informal environmental, social and governance (ESG) policies in place, 48% cite "a competitive differentiator" as the top driving factor for pursuing ESG initiatives.

"Manufacturers are continuing to seek opportunities for profitable growth but are realizing that uncertainty in workforce availability is impacting quality, along with their ability to meet evolving customer needs," said Veena Lakkundi, senior vice president for strategy and corporate development at Rockwell Automation.

"The survey found that smart manufacturing technology is enabling manufacturers of all sizes to optimize more resilient, agile, and sustainable solutions that accelerate transformation. If we've learned anything from history, it's that organisations that invest in innovation, with a bias for action, during times of uncertainty can outpace competitors."

Veena Lakkundi

The survey concludes that technology is crucial to mitigating risk and delivering growth. However, for one-third of manufacturers globally, the range of available systems and platforms is leading to "technology paralysis" – an inability to decide between solutions.

Manufacturers can overcome this indecision by choosing a partner with relevant industry expertise and experience who can advise and guide them in implementing a fit-for-purpose solution to achieve desired outcomes.