The economic boom of post-war Japan after World War II produced much of the infrastructure – roads, bridges and high-rise buildings to name a few – still used today.

But now, the country is faced with the challenge of monitoring the structural integrity of all these physical assets, many of them have deteriorated significantly. According to official estimates, about 25% of bridges over 2 metre in length have passed the 50-year mark in 2018, with this number of the percentage going up to 63% by 2033.

The structural degradation has caused tragic accidents—most recently, approximately 130 meters worth of concrete panels on the roof of an expressway tunnel collapsed, resulting to multiple deaths in 2012.

Confounding the problem is an aging population that leads to a shortage of skilled workers who can conduct the structural monitoring of Japan’s vast infrastructure.

As structural monitoring of existing facilities has become a national imperative, Toshiba has developed a new system for structural health monitoring. The system deploys sensors that help visualise the interior health of structures and allows for efficient and comprehensive inspections.

“After the tunnel collapsed, a law was tightened to have regular inspections of bridges every five years. However, the conventional inspection methods have relied on direct visual checks and hammer tests, where a worker hits the bridge with a hammer and checks its condition by the sound it makes. This made it difficult to distinguish condition when there was above a certain level of deterioration, with no discernible changes in the surface and the sound,” said Kazuo Watabe, chief research scientist of the Mechanical Systems Laboratory at Toshiba’s R&D Center.

Detecting hidden internal damage

Toshiba’s new structural health monitoring system was developed as part of “Robot and Sensor System Development Project for Infrastructure Maintenance and Disaster Survey” under the New Energy and Industrial Technology Development Organization (NEDO). The company conducted its research in collaboration with Professor Tomoki Shiotani of Kyoto University.

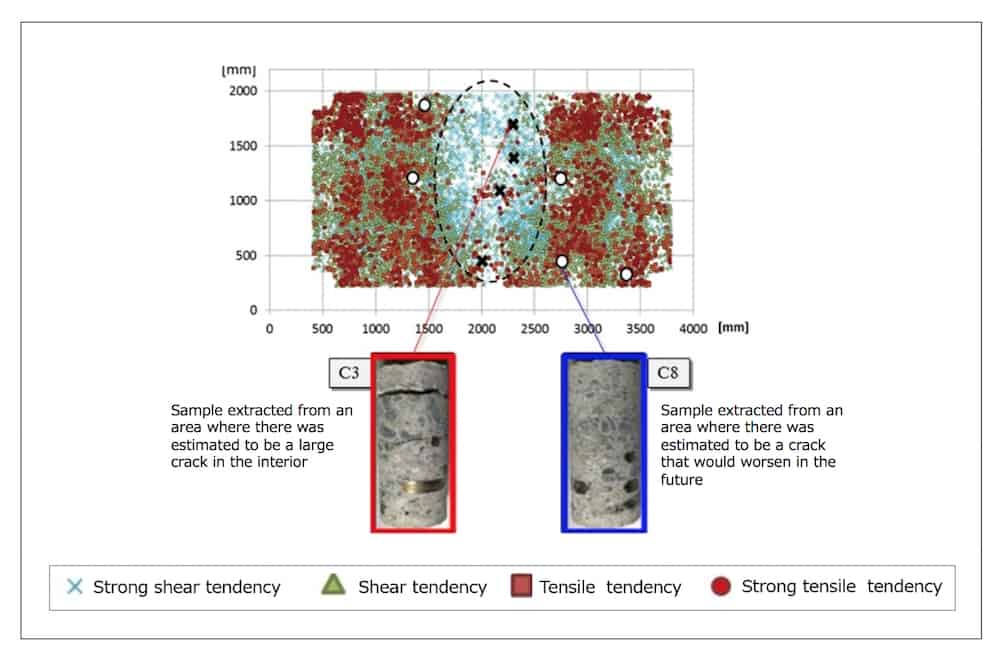

The most significant aspect of Toshiba's structural health monitoring system is the brand-new sensing technology, which allows the system to visualize damage on the inside of the concrete, in areas where workers cannot see directly, and determine the level of deterioration. This technology provides the opportunity to prioritise bridges that needs urgent maintenance, and helps better the use of limited labour and budget.

Takashi Usui, research scientist at Mechanical Systems Laboratory of Toshiba’s R&D Center, said that we took advantage of multiple resources within Toshiba in developing this sensing technology.

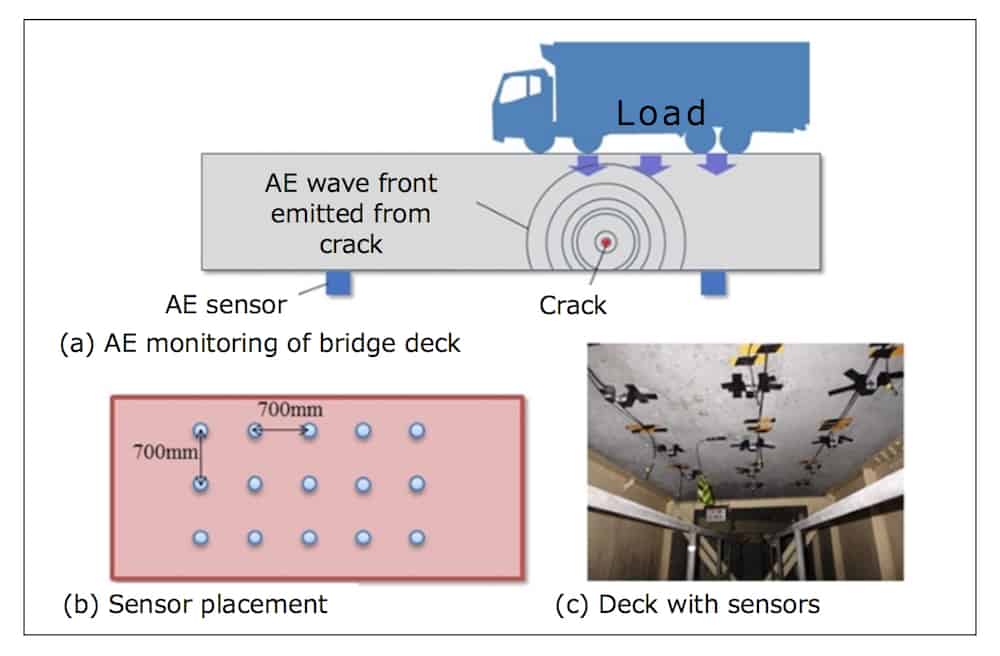

The new sensing technology is elastic waves, a wave emitted by miniscule forms of damage in structures. The vibrations induced when a vehicle drives on the bridge causes several dozen to several hundred kHz worth of elastic waves to be emitted from cracks in the structures. The sensor measures these waves from where it is attached to the deck of the bridge, using a test called AE Method.

“AE sensors themselves have actually been used in different areas, but not many comprehensive systems are implemented in multiple areas. We were able to create an entire measurement system with AE sensors, including a system that processes the received signals, and quantifies degree of deterioration by the frequency and arrival times of the elastic waves. And I’m sure we were only able to do that because of the resources available to us at Toshiba,” says Usui.

Toshiba sees potential in applying the AE method to roads, buildings, and even large-scale industrial machinery.

Unexpected benefit

Meanwhile, Toshiba discovered an unexpected benefit of the system in the verification tests they’ve been conducting.

“We were able to gain some unexpected data from a guerrilla rainstorm (a sudden, intense rainstorm) that occurred during our test. Generally, in a system that uses elastic waves, rain is considered noise, and verifiers want to avoid it as much as possible. But in this case, we found that the impact of the raindrops hitting the road caused elastic waves to be emitted, and that the calculated distribution of the raindrops reflects the position of cracks in the interior of the bridge deck,” said Watabe.

This means that they could, potentially reduce the amount of time required for the sensing process using something like a sprinkler truck instead of a guerrilla rainstorm. In this happy coincidence, they had managed to acquire several days’ worth of data (of cars running back and forth on the bridge) in about 10 minutes of guerrilla rainstorm. What’s more, this had opened up previously unexplored possibilities for this system of structural health monitoring. If there was heavy rain, they could make use of every raindrop to sense deterioration, even in areas with less traffic.

“Looking even further, I’d say we may be able to apply the same kind of monitoring to roads, buildings, and even large-scale industrial machinery in the future. This issue of structural deterioration is going to occur in a variety of fields, and we’re confident that we’ll be able to come up with many different ways to implement this system,” said Usui.

For now, Toshiba will carry out verification tests, gather data, and improving system reliability, with an aim to reduce labour and cost for the maintenance of social infrastructure.