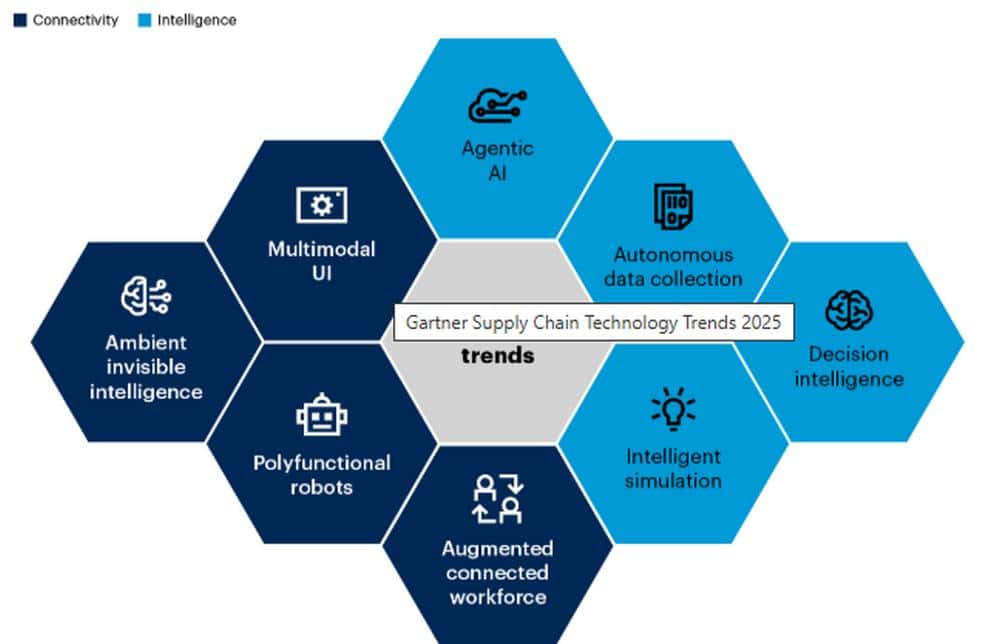

As the supply chain ecosystem continue to ride the rollercoaster of macroeconomic turbulence caused by geopolitical uncertainties, on-going transformation initiatives, and relentless cyber threats, Gartner lists its 10 technolog trends that chief supply chain officers (CSCOs) in Asia may want to look at o enhance operational efficiency and adapt to the rapidly changing landscape of global commerce.

Top trends in supply chain technology in 2025

“This year’s trends highlight the transformative potential of connectivity and intelligence in supply chains, enabling leaders to enhance operational efficiency and adaptability,” said Christian Titze, VP analyst and chief of Research in Gartner’s Supply Chain practice. “By evaluating and integrating advanced technologies like agentic AI and intelligent simulation, organizations can achieve specific goals, foster innovation and achieve long-term competitive advantage.”

One of the most significant trends is Agentic AI, which offers a virtual workforce of intelligent agents capable of making autonomous decisions. This innovation allows CSCOs to optimise inventory management and enhance responsiveness to real-time demand fluctuations. By leveraging Agentic AI, organisations can achieve a competitive edge through improved adaptability and efficiency.

Another critical trend is Ambient Invisible Intelligence, which utilises ultra-low-cost smart tags and sensors. This technology provides real-time visibility into end-to-end supply chains, allowing for large-scale tracking of goods, particularly perishables. Enhanced traceability not only ensures compliance with environmental regulations but also strengthens overall supply chain integrity.

The Augmented Connected Workforce (ACWF) is also gaining traction among supply chain executives. By digitising standard operating procedures and employing digital tools, organisations can improve decision-making accuracy and address the skills gap prevalent in today’s workforce. ACWF initiatives streamline employee onboarding and boost productivity across manufacturing and logistics operations.

Additionally, the introduction of a Multimodal User Interface (UI) transforms how users interact with supply chain systems. This technology enhances user experience by allowing communication through various modes, such as voice commands and gesture-based controls. Enhanced interfaces improve driver safety and overall operational efficiency.

Polyfunctional Robots represent another exciting development. These versatile machines can perform multiple tasks, from sorting to packaging, thereby reducing reliance on human labour. Their adaptability makes them invaluable in warehouses, where efficiency is paramount.

Moreover, Autonomous Data Collection technologies, including drones and mobile robots, are revolutionising data capture in supply chains. By automating inventory checks and other data-gathering processes, these tools significantly enhance productivity while minimising manual errors and risks.

Finally, Decision Intelligence (DI) and Intelligent Simulation are set to change the decision-making landscape. DI combines various analytical tools to support and automate decisions, while intelligent simulation integrates AI and machine learning into traditional models, providing enhanced predictive capabilities. These technologies empower CSCOs to optimise logistics routes and improve overall cost efficiency.

The supply chain landscape in 2025 will be shaped by these emerging technologies, enabling CSCOs in Asia to navigate complexities and drive innovation. By prioritising these trends, leaders can position their organisations for success in an increasingly competitive environment.