In its new whitepaper, 70 Technology Trends That Will—and Will Not—Shape 2022, ABI Research chief research officer Stuart Carlaw commented that: “The fallout from COVID-19 prevention measures, the process of transitioning from pandemic to endemic disease, and global political tensions weigh heavily on the coming year’s fortunes.”

WHAT WILL HAPPEN

Rise of digital twin marketplaces

Manufacturers need a range of capabilities to deploy digital twins, including Computer-Aided Design (CAD) modelling, connectivity, cloud computing, Industrial Internet of Things (IIoT) software platforms, remote monitoring, hardware for shop floor workers (tablets, AR glasses), physics-based simulation, ML, and systems integration.

This is because digital twins are not a technology, but a composition of solutions aimed at bridging the physical and digital worlds, from design through simulation, manufacturing, assembly, and after-sales service and support.

Over the last few years, digital twins have grown from a concept to become mainstream with the help of IIoT dashboards and near-real-time reporting. This level of maturity has been accompanied by new thought constructs, such as the use and implementation of AI at scale, changing requirements like the need for model libraries and standards bodies, and soon, the emergence of digital twin marketplaces that enable Independent Software Vendors (ISVs and other third parties to build relevant tools for the ecosystem.

These tools are essential for continued value creation and the wider democratization and adoption of digital twins. Spending on industrial digital twins will grow from US$4.6 billion in 2022 to US$33.9 billion in 2030 at a 28% Compound Annual Growth Rate (CAGR).

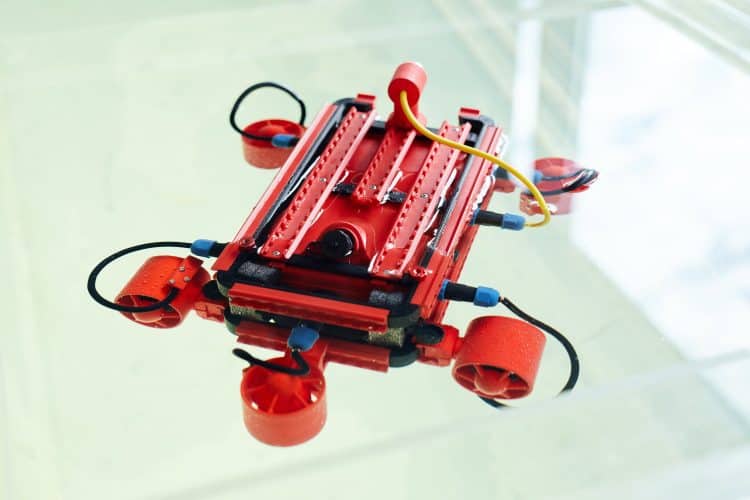

Hardware-based robot operating system optimization

Robotics processor vendors will increasingly offer Robot Operating System (ROS)-based solutions for hardware acceleration across the entirety of robotics offerings.

This should help tackle the problem of system integration and entice developers to adopt more off-the-shelf processors and hardware. Furthermore, the hardware-software optimization will provide a set of benchmarks and standards for the field, which is fairly fragmented now, accelerating the time-to-market.

As a total of 45,000 cobots and 452,000 mobile robots are expected to be shipped in 2022, a 65% and 51% Y-o-Y growth, end users are expected to benefit from the tighter integration.

WHAT WILL NOT HAPPEN

5G Will Not Permeate the Production Line

As of July 2021, there were 84 sites with publicly announced private cellular network (4G/5G) deployments. All are at large companies and facilities, with examples including ABB, Airbus, BASF, Daimler AG, Ford, Haier, Konecranes, and Nippon Steel.

While important, current deployments are mostly used as campus networks or in a lab or intermediary production development centre for non-industrial production applications. Standards work by 3GPP and 5G-ACIA continues to advance adoption and use of the technology; however, the device ecosystem and implementation/management functions lag.

These larger companies and locations have started to evaluate the cost and benefits of different deployment scenarios (a key progression); however, 5G will not be relied upon for production-critical applications at scale until 2024.

The democratization of robotics expertise

While the emergence of ROS and various robotics startups will offer real advances in the short term, robotics suffers from a significant shortage in expertise. In the long run, this will have an adverse effect on development and commercialization.

Considerable investment in resource- and time-intensive areas requiring experts from different fields is badly needed, but this will not happen anytime soon.