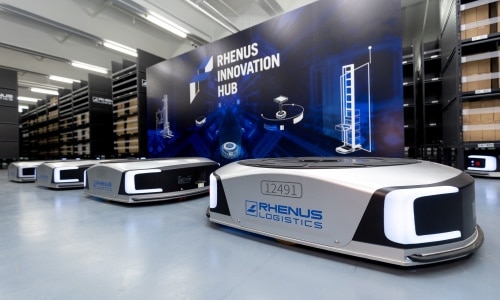

Amid the labour shortage caused by the COVID-19 pandemic, global logistics provider Rhenus further automates its warehousing operations in Hong Kong by recently deploying autonomous mobile robots (AMRs).

The proof of concept (POC) project is part of Rhenus ongoing strategy to deepen IT-driven digitalisation by tapping into smart logistics to build a sustainable and robust supply chain.

The company tapped Geek+ as technology partner providing advanced robotics and AI technologies.

The Rhenus Hong Kong warehouse will use Geek+ Goods-to-person solutions. Robots will be used as part of the system to automatically bring goods to the operators, achieving 99.99% accuracy. The solution also helps maximise warehouse storage as aisle space is minimised.

"Our goal is to provide the best and most innovative logistics service to achieve faster and more flexible movement of goods, to cater to the rapid growth in e-commerce. By working closely with Geek+, we not only realise warehouse digitalisation, but also improve operational efficiency and accuracy, translating to greater cost-savings for customers in the long run,” said Cliff Xu, CEO of Rhenus Air & Ocean Greater China.

With the Geek+ solution, Rhenus Hong Kong can handle large volumes of orders, flexibly meet rapidly changing SKUs, and improve order-fulfilment performance. The Hong Kong site will be the first smart Rhenus warehouse in the Asia-Pacific.

One of the features of the AI-driven system are Geek+'s proprietary algorithms. They optimise order combinations and adjust the inventory layouts in real time, maximising efficiency. In the Rhenus Hong Kong warehouse, over 2,000 SKUs of cosmetic products are constantly arranged according to popularity and expiry date.

"We believe that the smart warehouse upgrade is the only answer to the rapid growth of e-commerce business and growing customer expectations. We will continue to support Rhenus with tailored solutions that best fit their multi-customer business,” said Lit Fung, VP, managing director APAC, UK and Americas at Geek+.