Logistics has long been known as a traditional industry associated with manual labour and repetitive tasks. Often held back by legacy processes and dated IT systems, logistics companies are increasingly aware of the need to harness technology to stay competitive in a fast-moving industry.

The onset of the COVI9-19 last year and the disruptions it brought to the global supply chain underscored the need for the logistics industry to accelerate their digital transformation projects in the quest for increased automation.

Long before the pandemic hit, DHL Express introduced solutions to streamline vital processes, automate time-consuming repetitive tasks, and helped teams become more productive. These include autonomous guided vehicles to enhance our operations, chatbots to complement customer service operations, and shipment sensors with track-and-trace capabilities.

“We were cognizant that digital transformation was an imperative to maintain and elevate our service levels as a logistics provider. The pandemic accelerated our plans to allow our work force to collaborate and work virtually from any location. We also fast-tracked our adoption and rollout of technologies, such as live chat and digital assistants, which were crucial in helping us cope with an unprecedented demand surge worldwide," said Jimmy Yeoh, chief information officer, DHL Express Asia Pacific.

DHL Express has 3,200 facilities across more than 220 countries and territories worldwide, delivering close to 500 million shipments a year based on 2020 figures.

Taking the lead in technology innovations

According to DHL Express Asia Pacific CEO Ken Lee, embarking on digital transformation projects has driven greater efficiencies and higher productivity across their organisation.

At DHL Express, solutions such as the AI-based Advanced Quality Control Center (AQCC) system installed in each facility is designed to monitor shipment movements and flag issues in real time. It ensures parcels in transit move smoothly at every stage of their journey.

The system triggers alerts when shipments in transit are stalled. The platform’s data analytics engine then kicks up to quickly identify to location of these “exceptions” and their projected routes are mapped. The company’s team of analysts then hunker down to implement corrective actions to ensure these shipments can still arrive at their destinations on time.

Furthermore, the AQCC system uses AI and machine learning to identify root causes and recommend actions for continuous improvement.

Besides the AQCC system, here is a peek of the various digital transformation projects that DHL Express have done in recent years:

- Automatic flyer sorting with DHLBot: Sorts flyers to route level with 99% accuracy. It improves sorting efficiency while minimising human interaction (for safety during Covid-19).

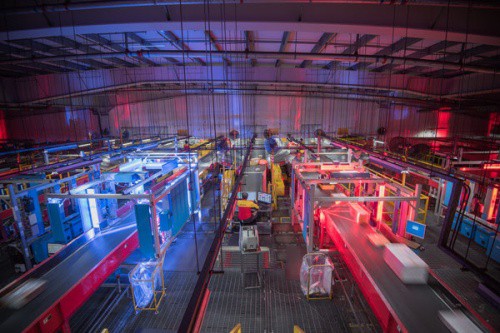

Automated Guided Vehicles (AGVs): Intelligently senses the environment and ferries shipments, cargo pallets, and containers safely and efficiently. It helps to scale throughput capacity as and when needed.

Automated Guided Vehicles (AGVs): Intelligently senses the environment and ferries shipments, cargo pallets, and containers safely and efficiently. It helps to scale throughput capacity as and when needed. Autonomous mobile robots: Serve as autonomous "couriers" that provide on-demand deliveries. They are equipped with sensors and AI-powered avoidance system to navigate to their respective destination.

Autonomous mobile robots: Serve as autonomous "couriers" that provide on-demand deliveries. They are equipped with sensors and AI-powered avoidance system to navigate to their respective destination.- Chatbots for 24/7 customer service: Allows customers to receive bite-sized shipping information and track shipments on-the-go. It is designed to instantly address commonly asked questions.

- On-Demand Delivery (ODD) online portal: Offers customers the flexibility to schedule contactless deliveries for shipments at their own convenience. Customers can choose from six alternative delivery options if they are unable to receive the shipment on the estimated delivery date.

QR code labellers for parcel returns: Allows customers to manage parcel returns digitally by getting a QR code online. This reduces physical contact for ad-hoc customers by replacing physical airway bills.

QR code labellers for parcel returns: Allows customers to manage parcel returns digitally by getting a QR code online. This reduces physical contact for ad-hoc customers by replacing physical airway bills. Route optimisation for faster deliveries: Enables couriers to plan their routes more effectively, thus improving productivity and fuel efficiency. It shortens delivery time to customers.

Route optimisation for faster deliveries: Enables couriers to plan their routes more effectively, thus improving productivity and fuel efficiency. It shortens delivery time to customers.

"By constantly listening to our customers' needs, we have implemented technological innovations that are relevant and sensible for our customers, employees and operations," Lee said.

Indeed, the Deutsche Post DHL Group (DPDHL Group) is investing over EUR2 billion on digital transformation projects from 2021 to 2025 to improve the experience of customers and employees, while also increasing operational excellence. This is in line with the group’s Strategy 2025 goal of delivering excellence in a digital world.