Automotive industry supplier Denso Corporation has developed a factory-IoT platform to connect production factories worldwide with IT and IoT technologies, based on the concept of "as if under one roof”.

“By connecting factories around the world in the cloud, it strengthens DENSO's global production system, enables factories to respond immediately to production changes based on local demand, and allows production teams to conduct real-time analysis of the movement of workers and operation statuses of different facilities,” the Japan-based company said in a statement.

The US$48.3 billion global mobility supplier develops advanced technology and components for nearly every vehicle make and model on the road today. With manufacturing at its core, Denso invests in its 221 facilities in 35 countries to produce thermal, powertrain, mobility, electrification, & electronic systems, to create jobs that directly change how the world moves. The company has over 170,000 employees across the world.

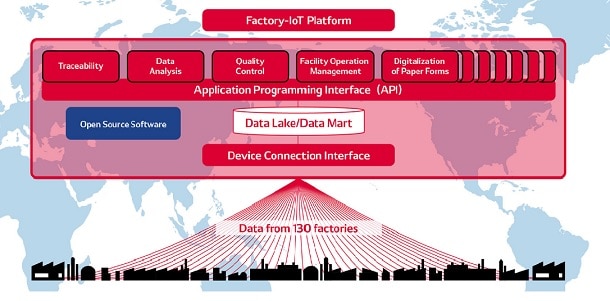

The new factory-IoT platform is touted to be the first in-house development of a cloud-native platform using open-source-software in the automotive supplier industry. It stores data collected from a variety of equipment at various production sites in a single cloud that can be used freely across Denso’s organisation.

The new factory-IoT platform is touted to be the first in-house development of a cloud-native platform using open-source-software in the automotive supplier industry. It stores data collected from a variety of equipment at various production sites in a single cloud that can be used freely across Denso’s organisation.

Denso spent roughly two years to develop the platform, focusing on three points:

- Giving in-house software engineers the ability to keep improving and evolving the platform even after it has been put into operation;

- Enhancing the company's ability to leverage agile development techniques, which consists of short cycles of development;

- And, allowing DENSO to share data with internal and external partners as an open platform so that they can work together to improve and develop applications. As a result, DENSO is the first in the automotive supplier industry to develop its own cloud-native Factory-IoT platform instead of using existing services.

The factory-IoT platform was implemented in October last year. Today, it links 130 Denso factories around the world.

“We will promote education to make full use of the platform and develop application developers. DENSO aims to be a manufacturer where employees can work swiftly and collaboratively by accelerating improvements in IT and IoT technologies,” the company said.

In addition, technical engineers in the field can incorporate digital power using their own software into the physical improvement activities accumulated over many years, which will further accelerate gains in efficiency, quality and cost savings. For example, by linking various devices, it is possible to notify the operator of equipment abnormalities and more.

“At the same time, by delivering high-quality products to as many people as possible. Denso is contributing to the realisation of a safe and secure automotive society around the world,” the company said.