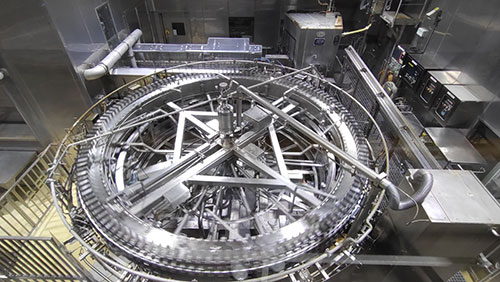

Suntory Beer is currently implementing an AI-based facility anomaly detection system at the new can filling line at its Natural Water Beer Plan in Kyoto Japan.

Traditionally, at production lines at manufacturing sites where mass production is undertaken, field personnel mainly use sensor data from equipment to monitor usage thresholds. However, there is a need for experience and know-how in order to understand the fine changes in individual data, and passing these skills along is a challenge.

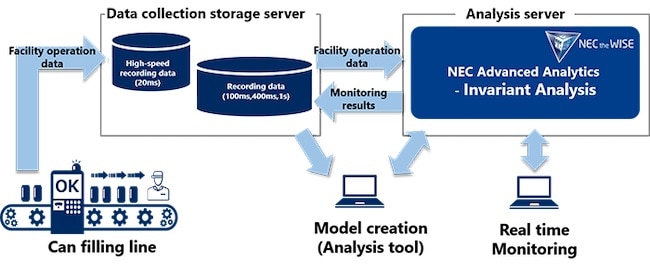

The beverage maker’s own in-house IT team at Suntory System Technology is currently working with NEC Corporation to implement the latter’s NEC Advanced Analytics-Invariant Analysis system, which is set to go live in late May.

Using AI to sift anomalies in sensor data

The new AI-based anomaly detection system from NEC Corporation will automatically discover the relationships between approximately 1,500 sensors at the new can filling line at Suntory’s Natural Water Plant, which will start operating in April.

The system will trigger alarms when changes occur, thereby detecting equipment anomalies at an early stage and helping to resolve them faster.

"Through the provision of this system, NEC is supporting the stable operation of facilities, preserving expert know-how and experience, recognizing errors that are difficult to detect, and contributing to the DX of production lines," said Masayuki Ikeda, general manager, AI Analytics Division, NEC Corporation.

The system uses Invariant Analysis Technology, part of NEC's leading-edge AI technology group, NEC the WISE. By collecting and analysing a large amount of time-series data from a large number of sensors installed in facilities through control systems such as PLCs (Programmable Logic Controller), modelling invariant relationships between sensors (invariants) and comparing changes between predicted data with actual data, users can detect "irregular" occurrences at an early stage.

This system takes advantage of the features of White Box AI and provides information necessary for taking action at maintenance sites, such as where and why functions are performing abnormally. When modelling, users can easily visualise conditions by simply entering the sensor information they want to see with the time that those sensors were operating.

Moreover, NEC will install microphones near filling machines in order to analyse when sounds are different from usual, which could possibly indicate an abnormality with the system.

In the future, it is expected that these advancements could help to reduce the number of people required for maintenance work, while helping to detect abnormalities more quickly.