Autonomous driving LiDAR perception solution provider RoboSense has rolled out its LiDAR RS-LiDAR-M1Simple(Simple Sensor Version), which is less than half the size of the previous version, with dimensions of 4.3” x 1.9” x 4.7” (110mm x 50mm x 120mm).

It is equipped with enhanced hardware performance virtually equal to the serial production version provided to various car OEMs. The main body design of this automotive-grade solid-state LiDAR is finalised and ready for shipment.

RoboSense technologies are widely used in autonomous driving logistics vehicles, buses, and passenger cars, with partners including SAIC, BAIC, Baidu, Cainiao Network, JD.com, Samsung, ControlWorks, Aidrivers, and more.

The new sensor is being demonstrated this week at CES 2020 in Las Vegas, with an on-vehicle public road test. The RS-LiDAR-M1Smart main body is embedded with an AI perception algorithm that fully takes advantage of LiDAR’s potential to transform conventional 3D LiDAR sensors to a full data analysis and comprehension system.

“The RS-LiDAR-M1 is an optimal choice for the serial production of self-driving cars, far superior to mechanical LiDAR. The sooner solid-state LiDAR is used, the sooner production will be accelerated to mass-market levels,” said Mark Qiu, RoboSense COO.

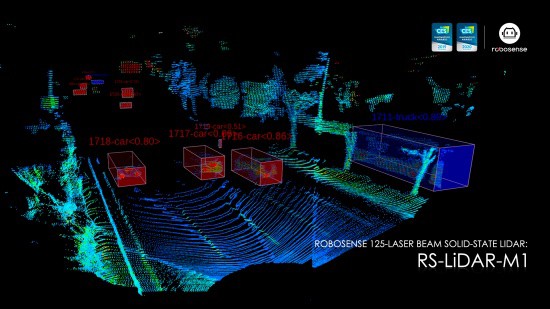

The major featRS-LiDAR-M1 Family Features:

- 125 laser beams with exceptional performance: the RS-LiDAR-M1 has a field of view of 120°*25°, which is the MEMS solid-state LiDAR’s largest field of view among released products worldwide. RoboSense uses 905nm lasers with low cost, automotive grade and small size instead of expensive 1550nm lasers. At the same time, RoboSense continuously breaks ranging ability limits to 150m at 10% NIST target, which is also MEMS solid-state LiDAR’s longest detection range.

- World’s smallest MEMS solid-state LiDAR: one-tenth the size of conventional 64-beam mechanical LiDAR. The RS-LiDAR-M1 can be easily embedded in the car’s body while still maintaining the vehicle’s appearance intact.

- Reduced parts from hundreds to dozens in comparison to traditional mechanical LiDARs for lower cost, shorter production time, and large-scale production capacity.

- Modular design: the scalability and layout flexibility of the optical module lay the foundation for subsequent MEMS LiDAR products and support the customization of products for different application cases.

- Stable and reliable: RoboSense fully implemented IATF16949 quality management system and ISO26262 functional safety standards, combining ISO16750 test requirement and other automotive-grade reliability specifications to verify the RS-LiDAR-M1 series of products.

- All-weather: In Vienna, Austria, the RS-LiDAR-M1 was tested for rain and fog under different light and wind speed conditions. The test results prove that the RS-LiDAR-M1 has met the standards, and the final mass-produced RS-LiDAR-M1 will adapt to all climatic and working conditions.

- Minimal wear and tear: as a solid-state LiDAR, the RS-LiDAR-M1 eliminates potential optoelectronic device failures due to mechanical rotation.

The RS-LiDAR-M1Smart is a comprehensive system with sensor hardware, AI point cloud algorithm, and chipsets, which provides an end-to-end customer environment perception solution. RoboSense’s powerful AI perception algorithm injects the sensor with structured semantic-level comprehensive information, focusing on the perception of moving objects.