With the acceleration of digitisation and widespread adoption of IoT, the safety, efficiency, maintenance and product quality of systems are being visualised and analysed based on data collected from a large number of sensors installed in various locations, such as plant systems, manufacturing lines and factories.

However, it is necessary to “systemise” data collection, storage, monitoring, analysis and other processes in order to use sensor data. Adding to this challenge, unique know-how such as knowledge about IoT systems and data analysis is required to construct this system, making it difficult for customers who have to do it themselves.

In addition, especially in the manufacturing industry, work processes are often based on the expertise of each plant or individual. Therefore, the loss of know-how due to the retirement of skilled personnel and lack of staff poses a serious challenge.

In order to solve these issues, Siemens and NEC Corporation have recently forged a partnership enhanced their products to enable greater visualization and analysis of sensor data. With this latest collaboration between the two companies, they will be providing a monitoring and analysis solution targeted at the manufacturing sector.

"Siemens is committed to creating partnerships that help customers realize digital transformation with Industrial IoT. Working with NEC can help provide MindSphere applications that improve customers' ability to add value to their digital transformation initiatives," said Kunihiko Horita, Japan country manager, Siemens Digital Industries Software.

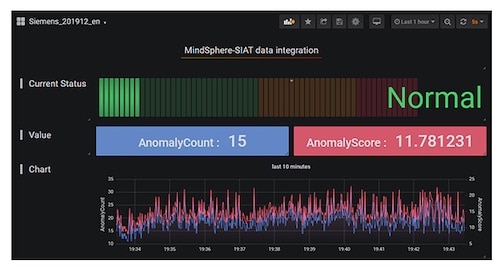

The solution combines Siemen’s Mindsphere, a cloud-based IoT operating system, with NEC’s System Invariant Analysis Technology (SIAT), which is part of the latter’s portfolio of AI technologies.

Mindsphere from Siemens that connects products, plants, systems, and machines, enabling companies to harness the wealth of data generated by the IoT with advanced analytics

On the other hand, SIAT from NEC is being used to automatically learn and model the behaviour of systems based on data gathered from a large number of sensors installed in large-scale, complex systems. It enables a manufacturing firm to visualisation their systems and see how they operate. The technology also allow these systems to operate safely and efficiently by proactively detecting errors using analytical models. At present, NEC has already installed approximately 100 such systems internationally.

"NEC will accelerate the digitisation of enterprises through the provision of solutions worldwide that leverage both companies' strengths,” said Osamu Fujikawa, senior vice president, NEC Corporation. “NEC will continue to address diversifying needs by fusing real and digital technologies as well as by leveraging advanced technologies such as AI and IoT.”

The new collaboration enables both companies to provide total data collection, storage, monitoring and analysis, including customisation according to customer needs. Specifically, MindSphere is being used to collect and accumulate field sensor data and NEC's System Invariant Analysis Technology system automatically monitors and analyses the data.

This solution will first be offered as a cloud solution for the manufacturing industry, then applied to factory systems, manufacturing lines, plant facilities and other equipment, as well as products that are produced using this equipment. This makes it easy to visualize and analyse vast amounts of sensor data, thereby contributing to increased productivity, reduced operational risk, product quality and the preservation of know-how.

The companies plan to target customers in manufacturing industries internationally, then expand to customers in other industries.