Gartner says smart factory operations can help supply chain leaders achieve many of their highest priorities, but the challenges are too often underestimated.

Successful smart factory initiatives require accompanying cultural and operational transformations that are slow by nature and in many cases will require entirely new organisational designs to integrate the new capabilities within the broader supply chain.

“Smart factory operations hold the allure of numerous benefits for supply chain leaders, from expanding lights out manufacturing capabilities to improving quality and solving labour challenges,” said Simon Jacobson, VP analyst in Gartner’s supply chain practice.

“The potential for transformational benefits can also present the biggest pitfall, as organisations may rush into launching smart factory initiatives without a clear understanding of the extent of the challenges facing them.” Simon Jacobson

Five top risks to avoid when launching new smart factory initiatives

Confusing factory optimisation with business model transformation: The optimisation benefits of a smart factory are confined to that single site. When smart factory initiatives are disconnected from the rest of the supply chain, the site level benefits can come at the expense of creating costly constraints elsewhere in the business. This risk can be mitigated by ensuring factory objectives are synchronised with supply chain operating models and enterprise digital ambitions, flexibility and automation opportunities.

Overlooking the scope of change management: New technology acquisition may be straightforward and relatively cheap. Underestimating the resulting changes to existing processes, integrations and new performance targets can drive up both cost and time. This risk can be managed in part by treating such changes as part of an enterprise-wide initiative that requires alignment between senior leadership and the utilisation of continuous improvement teams to ensure initiatives are properly sequenced.

Underestimating the complexity of aligning and converging IT, OT and ET: Governance for smart factories is not just centred on plant-business connections but also on how IT, operational technology (OT) and engineering technology (ET) are managed. These three are inseparable, and their convergence and alignment are critical as production models change.

To mitigate the complexity of this risk, supply chain leaders should familiarise themselves with alternative organisational models for IT/OT alignment and evolve governance and organisational structures in line with new production models.

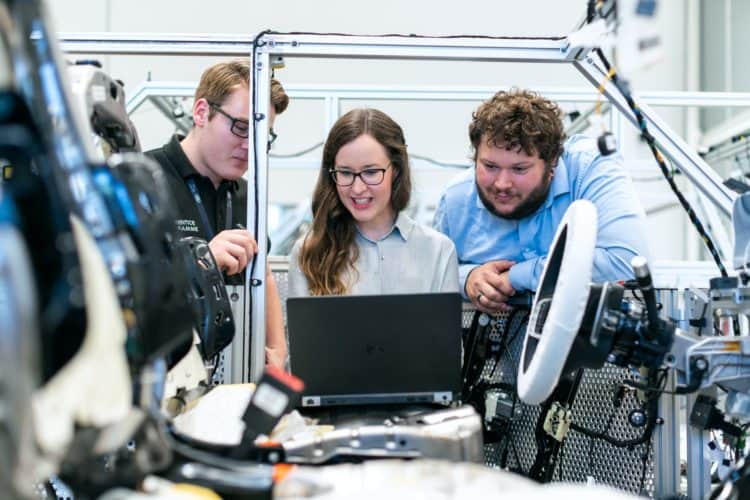

Insufficient funding for upskilling, reskilling and talent development: Modernising learning and development (L&D) programs to help associates learn, acquire and retain knowledge to acquiesce to new experiences is essential. So too is enabling employees to execute the work they are aligned to support through additional education and upskilling.

Narrowly focusing on a single use case and technology: As technology options increase and expand, too much focus on enabling technologies and the “art of the possible” can expose organisations to a significant IT backlog and technical debt.

The environment is complicated by the fact that there is no single dominant technology or vendor that fulfils all smart factory requirements. Technology purchases must be balanced between strategic considerations such as the ability to scale, along with the pragmatic, such as planning appropriately for operational disruptions.