The IBM commissioned study, APAC AI-Driven Industry 4.0: Building Tomorrow’s Industries, reveals that manufacturing, energy and utility organisations in the Asia Pacific (APAC) region are investing heavily in AI and Industry 4.0 capabilities, but many overestimate their actual readiness and struggle with fundamental challenges in holistic adoption.

Source: Ecosystm, IBM, 2025

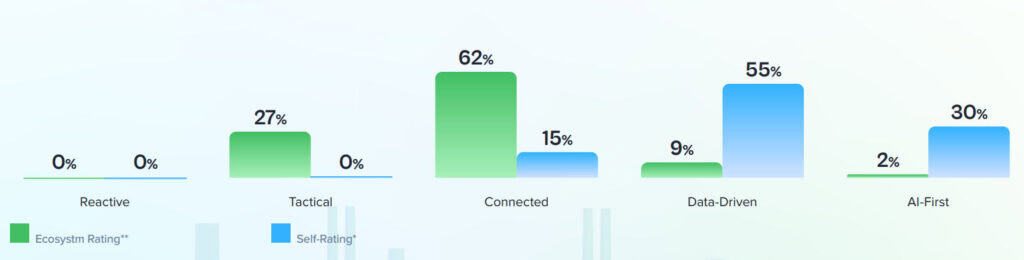

While 85% of respondents rated themselves as “Data-Driven” or “AI-First,” the study's objective assessment found that only 11% were in higher-maturity stages (9% Data-Driven; 2% AI-First). This significant gap suggests that strategic investments could be misaligned if leaders overestimate their level of maturity, potentially leading to missed bottlenecks and stalled progress in their transformation efforts.

Key barriers include:

- Strategic misalignment: Only 10% of organisations have a fully embedded Industry 4.0 strategy, while 70% have strategies without execution, siloed plans, or isolated pilots, risking fragmented and ineffective progress.

- People and adoption blind spots: 19% worry about employee resistance, and only 26% run formal upskilling or change-management programs, leaving only 16% confident in their in-house expertise.

- Siloed execution: Around 67% pursue ad hoc, department-level use cases, and 73% lack mechanisms for cross-team knowledge sharing, hampering collaboration and innovation.

- Slow core modernisation: Only 40% have broadly adopted predictive maintenance, and just 37% enjoy real-time supply-chain visibility, exposing organisations to downtime and disruptions.

- Limited AI integration: Although 63% focus AI on isolated processes, only 10% treat AI/ML as a strategic pillar, leaving end-to-end, intelligent operations largely unrealised.

Looking ahead, the transition from Industry 4.0 to Industry 5.0—where human-centricity, sustainability, and resilience become core—remains a major hurdle. Only 23% of organisations have customer feedback loops that inform strategic decisions in functions like Product Design and Operations, while 28% have invested in real-time sustainability tracking.

Despite these challenges, the report highlights several leading examples of Industry 4.0 in practice, such as Dongjin Semichem in South Korea and SMART Modular Technologies in Malaysia.

To bridge the gap between ambition and reality and set the stage for Industry 5.0, organisations must adopt a holistic, strategic approach, according to Ong Tun Kim, general manager of IBM manufacturing solutions. This includes establishing a value-driven tech strategy, leveraging core tech for cross-functional impact, treating data as a strategic asset, preparing for rapid technology integration, and embedding Industry 5.0 thinking today.

“As APAC organisations lean into these shifts, they can transform isolated proofs of concept into enterprise-scale solutions that drive competitive advantage and pave the way for a human-centric, resilient industrial future.” Ong Tun Kim